Table of contents

3 Energy and resources

3.1 Introduction

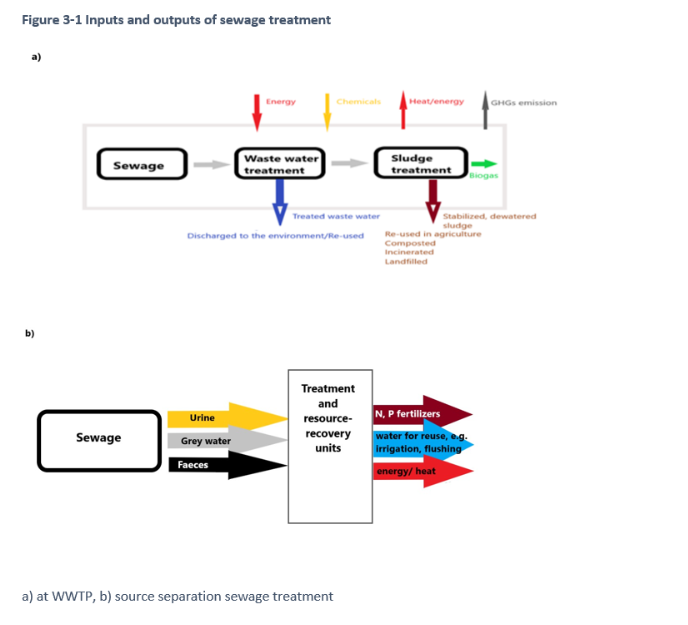

“Waste water treatment” is aimed at delivering clean water which is safe to be returned to the environment. It implies a linear process. However, our use of water is a transient stage of its natural cycle. Generation of sewage is largely predictable – a sustainable resource - allowing the infrastructure for its use and re-use to be established.

Waste water treatment currently uses at least 1% of total energy production in Europe (Ganora, 2019; Capodaglio and Olson, 2020). Pumping and treating water makes it the largest municipal use of energy. Energy efficiency can deliver savings on existing treatment costs, while demand for more intensive treatment is likely to drive up the energy requirement.

Meanwhile, sewage contains valuable resources. In waste water, this includes the water itself, but also heat, nutrients like nitrogen and phosphorus, and energy and other resources which can be derived from sewage sludge. Treated sewage sludge itself is valued for its nutrient and organic matter for agriculture in parts of Europe, but concern about mainly chemical contamination constrains its potential applications.

Taken together, the best-operating plants are able to meet environmental discharge limits and generate at least enough energy to power their own energy needs. The role of these “water resource factories” (Kehrein, 2020) can underpin a circular economy.

3.2 Energy use and efficiency

3.2.1 Sustainable use of resources

Minimising unnecessary use of resources is the first step towards sustainability, and often can provide monetary savings to operators. In the context of water, efficient use of this essential resource should be high priority, both because water can be in short supply, and because pumping and treatment are expensive in both energy and financial terms. Water saved from use also does not become waste water. The circular economy under the Green Deal sets out the EC’s ambitions for resource use, focusing on certain product chains and recognising the relationship between circularity and climate neutrality (EC, 2020).

Figure 3.1 summarises the inputs and outputs of a) urban waste water treatment, and b) sewage treatment separated at source, such as in certain types of decentralised treatment. While many of the products are similar, the main difference is scale – typically, (a) might apply from 50 people to millions, while currently (b) would mainly apply in Europe to pilot studies. This chapter mainly focuses on conventional treatment (a) as the dominant approach. However, the importance of smaller scale approaches (b) is increasing in innovative towns and operators.

Figure 3‑1 Inputs and outputs of sewage treatment

a) at WWTP, b) source separation sewage treatment

3.2.2 UWWTP energy use and efficiency

Energy use of an individual UWWTP is determined by the location, characteristics of sewage, treatment plant size, applied treatment technology and requirements on the quality of treated water. For example, location, elevation and slope of terrain determine whether the sewage will be gravity-fed or pumped to the UWWTP. Large plants treating larger volumes of sewage consume more energy, but typically have higher energy efficiency, owing to modern technologies and more advanced methods of operation, such as automatic regulation of processes (Ganora et al, 2019). Pumps, mechanical aerators or blowers and sludge handling systems account for the largest share of total energy consumption. The ENERWATER study showed that secondary treatment consumes the most energy in the treatment process, consuming between 64 – 74 % of the total energy used by UWWTPs (size ranging from below 2 000 p.e. to over 100 000 p.e.) (Longo et al, 2019).

Increasing energy costs, as well as pressure to reduce GHG emissions, have forced waste water treatment operators to look for ways to optimize energy consumption and navigate towards energy neutrality or even positivity, resulting in energy self-sufficiency or surplus. Reductions in energy consumption can be achieved through a variety of means. For example, the installation of energy-efficient aeration equipment in secondary treatment, improved process control, reduction of leakage, energy efficient approaches to sludge thickening/dewatering e.g. optimised sludge dewatering.

It is estimated that if all plants that use more than the current average amount of energy were shifted to the EU average value, the saving would be slightly more than 5 500 GWh/year. With highly stringent targets of efficiency improvement, saving of about 13 500 GWh/year could be expected (Ganora, 2019).

Text box: Improvements in energy efficiency

Bulgaria. The Sofia waste water treatment plant was commissioned in 1984 and historically consumed between 16 000 and 24 000 MWh electricity per year. Following the installation of combined heat and power (CHP) units in 2010, the energy produced annually on site rose from 15 288 MWh to 23 100 MWh in 2017. Measures implemented to reduce energy consumption included optimising the aeration process via air flow regulation, improving the anaerobic digestion process and utilising heat potential of on-site CHPs. This led to the plant producing 23 % more energy than was needed for its operation in 2017 (i.e. 4 300 MWh).

Source CircE. Energy production in Waste water treatment plant Kubratovo

Although the waste water treatment industry is not targeted by the EU Energy Efficiency Directive (EU, 2018), water utilities use benchmarking and energy audit procedures as tools to optimise energy consumption and greenhouse gas emissions in waste water treatment (Clos et al, 2020). Currently there is no systematic EU wide data collection of the energy efficiency of urban waste water treatment, as a standardized methodology at European level has not been adopted. ENERWATER has developed a methodology for assessing and improving energy efficiency and labelling of WWTPs, enabling a rapid audit and assessment for decision support.

3.3 Extracting resources from sewage and sewage sludge

3.3.1 Sewage sludge

Sewage sludge has been used for centuries as a fertiliser (Mulder, 2019). Addition of sewage sludge to land can provide nutrients such as nitrogen and phosphorus, and humus which can help the soil structure. Long term experiments show fertility enhancement after sewage sludge application, resulting from lower soil bulk density and higher soil carbon concentration (Börjesson and Kätterer, 2018). Where lime has been used to treat the sludge, the sludge can also help reduce the acidity of agricultural soils. The Sewage Sludge Directive (EEC, 1986) sets minimum treatment and standards to protect against health and pollution risks from sludge application to land. This old Directive is currently under evaluation (autumn 2021) and is planned for revision under the Green Deal. However, concerns remain that the treated sludge has effectively collected many of the persistent pollutants present in waste water, which then may be dispersed on to the land and become a source of diffuse pollution. A study in Norway considered microplastics in sludge, concluding that they could be a major source to the environment though with no assessment of the risk that this might present (Lusher et al, 2017). Knowledge about the sources and presence of microplastics in water is still limited (EEA, in prep).

A study investigating concentrations of metals and several pharmaceuticals in the sludge itself, from 11 UWWTPs over a year, calculated that concentrations would be below soil predicted no effect concentrations (UKWIR, 2018).

Across Europe, there are polarising opinions as to the fate of sewage sludge. In Germany there is a national strategy to end the application of sewage sludge to soil, with deadlines by 2032 for UWWTPs over 50 000 p.e., though sludge from smaller plants may still be used (Ricardo, 2021). In parallel, the ProgGress strategy requires the recovery of phosphorus from the sludge through mono-incineration (BMUB, 2016). Meanwhile, in Sweden, policy has shifted towards treated sludge going to land as part of a more circular approach (text box).

Text box: REVAQ-CERTIFIED WASTE WATER TREATMENT PLANTS IN SWEDEN

In Sweden, concerns about contaminants in sludge led to recommendations not to apply sludge to land during the early 2000s (Ricardo, 2021). However, in 2008 a collaboration between farmers, regulators and the water and food industries led to a certification scheme “REVAQ”, which assures the safety of sludge application to agricultural land, both in relation to the quality of soil and food and to water quality. This has led to an increase in the amount applied to land rising from 22 % in 2011 to 45 % in 2018 (Ricardo, 2021). Studies showed that “there is clear evidence that sludge fertiliser application supplies plant nutrients and humus that agriculture demands.” (Ministry of the Environment of Sweden, 2020).

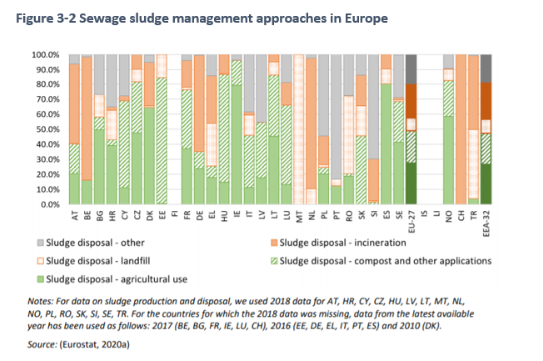

3.3.2 Sewage sludge production

The annual production of sewage sludge in the EU-32 was about 11.1 million tonnes in 2018 – about 17 kg per person (Anderson et al, 2021). 94% of this sludge was “disposed”. According to the Eurostat data used in that report, 27 % of the sewage sludge was used in agriculture, 25 % was incinerated, 21 % in compost and other applications, 9 % landfilled, and 19 % is used in another way.

Fig 3.2 shows a wide variation in the destinations for sewage sludge. Some countries have a high reliance on sending treated sewage to land, others incineration. Decisions are based partly on geography (e.g. availability of land) and also on the level of concern about pollutant loads in the sludge. There is a lack of data on sludge destinations for a number of European countries.

Figure 3.2 Sewage sludge management approaches in Europe

The cost for treatment + disposal of sludge in European countries has been estimated to reach, on average, approximately 200 per tonne of dry mass, according to the type of treatment and disposal.

With regards to sludge production, the treatment can have two objectives:

- recovery of materials or energy from sludge, utilising its resource potential;

- reduction of the amount of sludge produced, minimising waste.

The increase of the solid content in sludge by dewatering significantly reduces the volume of wet sludge for disposal. The reduction of dry mass of sludge leads to the reduction of solid content and volume. Methods are based on physical, mechanical, chemical, thermal and biological treatments. Most of them are aimed at solids solubilisation and disintegration of bacterial cells in sludge.

3.3.3 Resource recovery from sewage sludge

Owing to its high nutrient and organic matter content, and the energy content of dried sludge being comparable to that of woody biomass, sewage sludge is a potential secondary resource which can contribute to Europe’s transition to a circular economy (Ricardo, 2021). A potential obstacle for promoting sludge reuse and recovery stems from two policy objectives which may be in conflict:

- Protection of the environment and human health, which require that sludge for reuse complies with specific quality standards

- Resource efficiency promoting the use of sludge in agriculture, ensuring the recycling and recovery of valuable and finite nutrients.

Prevention of contamination of sewage by persistent, hazardous pollutants would allow recycling of sewage sludge on land without concerns that this might lead to diffuse pollution of soils, plants and water.

The estimated annual amount of nutrients that could be potentially recovered from sewage sludge produced in UWWTPs in the EU 27 ranges between 6 900 and 63 000 t of phosphorus and between 12 400 and 87 500 t of nitrogen (EEA-32: between 8 100 and 68 100 t of phosphorus and between 14 600 and 94 700 t of nitrogen). These amounts correspond respectively to 0.6-6% of total P fertilizers and 0.1-1% of total N fertilizers used in the EU in 2018 (Anderson et al, 2021).

Sludge could also contribute to renewable energy policy and targets as feedstock for energy generation, for example, through anaerobic digestion, incineration, pyrolysis and gasification. Estimations of additional energy potential (i.e. on top of that already recovered) has been subject to several studies assessing different sewage sludge options. Anderson et al (2021) estimated that the EU-27 could potentially recover between 1 800 GWh and 3 200 GWh of energy (net heat and electricity) through anaerobic digestion of the total generated sewage sludge currently intended for landfilling and composting, and 250 GWh (net electricity) through incineration of the total generated sewage sludge currently sent to landfill. This respectively represents 7 % , 13 % and 1 % of the total waste water sector energy needs in the EU-27 in 2018.

Using an alternative approach to calculation, JRC (ref) estimated that up to an additional 3285 GWh could potentially be recovered through anaerobic digestion of the total sewage sludge applied directly on land (30%) and 850 GWh resulting from incineration of sludge currently sent to landfill.

Selection of the optimum sewage sludge option for energy recovery must consider additional energy demands and GHG losses that arise from sludge processing. Energy savings and burdens need to be summed to derive a net value for assessed energy recovery options. The JRC study concluded that across different sewage sludge options, anaerobic digestion followed by use on land and co-incineration were the options that have the lowest GHG emissions.

Phosphorus

Phosphate rock has been identified as a critical raw material by the EC (EC, 2014). As an essential nutrient for the food system, reuse and recovery of phosphorus is of high priority. Policies under the Green Deal are addressing this: as part of the Circular Economy Action Plan, an integrated Nutrient Management Plan will be developed towards ensuring more sustainable application of nutrients and stimulating markets for recovered nutrients (EC, 2020). More broadly, the chemicals strategy for sustainability aims to promote the EU’s resilience of supply and sustainability of critical chemicals (EC, 2020).

The recovery of phosphorus from sewage sludge is a great challenge for countries where sewage sludge is incinerated and where nutrients are not being recycled. Various recovery processes exist, but they are not (yet) cost-effective and are therefore not yet applied to large scale UWWTPs. In Switzerland, regulatory changes foresee already that phosphorus recovery from sewage sludge will become mandatory. Some incineration plants already store sludge ash to recover the phosphorus in future.

Significant efforts have been made toward phosphorus recovery from sewage sludge based on the precipitation of phosphorus minerals e.g. in the form of struvites. These recovery technologies have been developed and put into operation largely in the Japan and Netherlands. Global demand for fertiliser is expected to increase by 4% a year due to population growth, so it can be expected that fertiliser recovery from waste water will gain further importance in the future. As well as conventional fertiliser, manure from livestock production also competes with fertiliser recovered from wastewater. In livestock-rich areas, manure may be a more cost-effective solution than treated sewage sludge, demonstrating again the need to apply local solutions to sewage treatment (Kehrein, 2020).

Other resources can be recovered from waste water and sewage sludge e.g. cellulose, bioplastics and alginic acid (Kehrein, 2020). Case studies illustrate a wide variety of possible recovery options, as well as the technical solutions for resource recovery e.g. UWWTP Amsterdam West which considered the recovered products alginic acid, bioplastic, cellulose, phosphorus and biogas (van der Hoek et al, 2016). Blockers preventing wide-scale application of resource recovery is not the availability of technology, but the lack of a planning and design methodology to identify and deploy the most sustainable solutions in a given context.

Actions leading to a more circular and sustainable economy revolve around reduction, reuse and recycling. Bottlenecks which can hinder the successful implementation of these can be grouped into three categories – Economics and value chain, Environment and health; and Society and policy. Recovering the value from sewage sludge illustrates aspects of bottlenecks, such as process costs, resource quality, market value and competition, and utilisation and application in the value chain assessment. Societal acceptance of the reuse of treated sewage sludge and resources recovered from it - overcoming the “yuck” factor - is an area with significant challenges.

3.3.4 Energy generation

Although UWWTPs use significant amounts of energy, the waste water theoretically contains between five and 10 times more chemical and thermal energy than needed for treatment. While only some of that energy can be recovered, it is possible for UWWTPs to be net energy producers (Riley et al, 2020).

Energy recovery of the chemical, thermal and hydrodynamic energy contained in sewage can provide electricity, biogas, steam and hot water. The energy content of sludge is typically similar to the energy content of low-grade coal (Stone et al. 2010). Energy can be generated from sewage sludge through pre-treatment by anaerobic digestion to produce biogas, and/or by incineration of the sludge. Biogas comprises of 60 – 70 % methane, and 30 – 40 % of carbon dioxide, trace amounts of other gases (e.g. hydrogen, hydrogen sulphide and nitrogen). Recovery of methane from biogas allows use in applications such as gas engines, electricity and/or heat. Serious accidents can occur with biogas generation (e.g. ) and the ability to meet necessary safety standards as part of the transition to greater sustainability is an important consideration.

In a study considering the potential for sludge currently landfilled in the EU-27, it was estimated that 7 - 13 % of UWWT energy needs (1 800 - 3 200 GWh[1]) could be met if that sludge were pre-treated by anaerobic digestion, although data were hard to come by (Anderson et al, 2021). This value represents an upper limit, as it would not be feasible to implement anaerobic digestion at all UWWTPs.

Most focus on energy generation from UWWT has been on anaerobic digestion and incineration, but operators may have other options. For instance, solar and wind energy generation, and heat recovered from the waste water itself. Solar panels installed on the roofs of Viikinmäki UWWTP in Finland generate c.210 MWh per year, or approximately 0.5 % of annual electricity use. Heat recovery from effluent waste water shows can be a much more significant source of energy, with potential heat energy recovery at up to 500 % of a plant’s heat energy consumption (Heinonen, pers. comm.). Actual solutions for a particular plant depend on local circumstances. For instance, incineration facilities may not be available, while biogas generation may not be economic at some smaller sites.

3.3.5 Water reuse

A perhaps less-recognised benefit of waste water treatment is that it enables others to reuse this precious resource. Cleaning the water allows use for other human activities, avoiding the abstraction from other, possibly non-renewable sources, such as groundwater.

The return of suitably-clean water is also important for aquatic life, ensuring there is sufficient water in lakes and rivers for life to persist. In parts of Europe, particularly the south, climate change is predicted to lower river discharge levels by up to 40% under a 3 oC temperature rise scenario (EEA, 2021). The WFD and Biodiversity Strategy (EC, 2020) consider ecological flows, i.e. the amount of water required for the aquatic ecosystem to continue to thrive and provide the services we rely upon (EC, 2016), but Member States are in early stages of implementation (EEA, 2021).

Water reuse has become a key part of water resources management in countries suffering highest water stress. Where water resources are abundant or less stressed (CSI 018), waste water reuse is driven by other factors, e.g. conservation of groundwater resources, reduction of costs; the precautionary principle. The primary use of reused water is in irrigation for agriculture, with the modelled potential for reuse shown in Figure 3.4. Other uses are in irrigation of urban space, groundwater recharge and river flow improvement.

Indirect reuse is the reuse of treated waste water which is placed into a water body such as a lake, river, or aquifer, and then some of it retrieved for later use. Direct reuse of treated waste water refers to the introduction of treated waste water via pipelines, storage tanks, and other infrastructure directly from a water treatment plant. For example, the distribution of treated waste water to be used directly in agricultural irrigation.

The quality requirement of reclaimed water is dictated by the final use (agricultural, industrial, urban, environmental, recreational) and this determines the treatment technology to be applied. Waste water treatment plants producing reclaimed water may be equipped with an advanced treatment composed of different technologies (e.g. coagulation/flocculation, filtration, ultrafiltration, reverse osmosis, disinfection) which determine investment, maintenance, and operating costs.

Implementation of water reuse is not widespread in the EU, though it is increasing in some Member States (Fig 3.x). It has been estimated that the potential for treated urban effluents in the EU is six times higher than current level of reuse (Pistocchi et al, 2017). In countries with significant problems of water stress or water scarcity, water reuse practice has been developed, facilitated by national guidelines providing regulatory reference on water reuse practices. Data are hard to come by but suggest that Cyprus and Malta reuse more than 90% of their waste water , followed by Greece, Malta, Portugal, Italy and Spain, where the share of reused urban effluent range between 41 and 12%. Water reuse schemes have been locally applied in other EU countries, e.g. Belgium and Germany, for purposes such as urban irrigation, industrial uses, and aquifer recharge. In Sweden, a key driver was the protection of coastal water quality and conservation of groundwater resources.

Figure 3‑3 Water reuse in Mediterranean EU Member States

Figure 3‑4 Modelled potential of water reuse for agricultural irrigation in the EU

Note: Average irrigation water requirement, computed with the EPIC model

The reuse of treated water helps to increase the available amount of water at a relatively low marginal cost. The treated effluent quality can be adapted to the users’ needs, allowing economic efficiency. Costs of treated waste water can be lower where uses are closer to each other, owing to savings in infrastructure and transport costs. However, issues such as social acceptability of reusing “waste water”, costs in comparison to abstracted water and the infrastructure investment which may be needed can act against implementation of water reuse. Despite the Water Reuse Regulation of 2020, which recognises that water reuse will become more necessary and so set standards for the agricultural reuse of waste water, numerous barriers to water reuse still exist in Europe. Drivers for reuse include population pressure and water scarcity. A coherent legislation framework (currently being established in the frame of Circular Economy Plan) is needed, which provides flexibility for treated water quality depending on destination uses, and allows for governance structures enabling interdependencies between waste water providers and users of reused water.

Text box /case studies: Waste water reuse

Case study – waste water reuse for irrigation - Milan, Italy

Reuse of wastewater for irrigation reduces the quantity of drinking water used for irrigation and guarantees supply of high-quality water for farmers in the Milan area. All the water treated by the Nosedo and San Rocco plants meets the limits applicable to reuse for irrigation purposes, as certified by ARPA, and is used to irrigate a substantial portion of farmland with a surface area of over 100 km2. This practice for irrigating the rural areas outside the city, has its roots in the past and reflects the historical and cultural heritage of the area.

Case study – beer brewed using recycled waste water - Čížová microbrewery – Czechia

To raise public awareness of the importance of preserving water, together with Veolia, Čížová microbrewery in the Czech Republic developed a beer brewed using recycled waste water. Veolia recovers waste water at its Prague treatment plant and then treats the water using a mobile, membrane water reclamation unit. The treatment comprises coagulation, followed by ultrafiltration and reverse osmosis, where ultra-fine synthetic membranes serve as a filter that lets water pass through and retains suspended solids and other substances, such as micro-organisms and viruses. The water is then filtered through granulated activated carbon and disinfected. The advantage of membrane technology is that the filtration does not need added chemicals and new types of membranes have low energy consumption. The treated water is then transported to Čížová microbrewery, where it is used to brew ERKO beer. 15 hectoliters of lager were produced in May 2019 and more continue to be produced as the interest in supporting recycling schemes grows.

3.4 Low input sewage treatment

Options for waste water treatment are constrained by local factors. A densely populated city, with many industries and limited land availability presents one extreme, while sparsely populated, rural areas represent another. Construction of waste water treatment plant can involve greenhouse gas-intensive activities and high costs, in both the building and operating phases. Alternative solutions can use less energy, release fewer harmful emissions and provide local benefits and control (Water Projects online, 2019)

A focus on nature-based solutions under the EU’s Biodiversity Strategy (EC, 2020) brings attention to small-scale solutions to sewage treatment. Natural wetland systems are able to transform and/or remove various pollutants through a series of physical, biological, and chemical processes, and therefore improve water quality. These processes are mimicked in so-called “constructed“ wetlands. These treat waste water near its source, without high demands on infrastructure and operational costs, while enabling recovery and use of resources from waste water and increasing green space in rural or peri-urban areas. In a study on Slovenia, the JRC compared various solutions in terms of cost-effectiveness and socioeconomic acceptability. They found that nature-based solutions were a preferred option for areas with a predominance of rural, scattered dwellings and small settlements. The concept was proposed as a mainstream solution for the less urbanized areas of the Lower Danube region (Pistocchi et al, 2020).

Owing to their low costs and low maintenance, constructed wetlands are popular in low-income regions. But they can be also used as a decentralised approach for blocks of buildings, neighbourhoods, commercial facilities, isolated communities and remote areas, etc. Reduction of nutrient concentrations can deliver similar results to tertiary treatment (Cooper et al, 2020). Studies on micropollutants suggest that such constructed wetlands can be effective at preventing release to water (Gorito et al, 2018) though care must be taken to ensure oxidation conditions in constructed wetlands are appropriate to address organic micropollutants (Reyes Contreras et al, 2019).

Figure 3‑5 Comparison of needs for land, energy and maintenance between constructed wetlands and conventional urban waste water treatment

Source: Stefanakis, 2019

Recent technological advances have managed to significantly close the gap with conventional, mechanical technologies in terms of land requirement (e.g. the compact, mobile aerated constructed wetland) (Stefanakis, 2019). Such solutions can be integrated in urban and peri-urban areas for wastewater treatment and urban runoff control and management, following the decentralised approach. For example, the INNOQUA Horizon 2020 project investigated a modular system for water treatment based on the purifying capacity of biological microorganisms (earthworms, zooplankton and microalgae), developing a technology for decentralised waste water treatment (INNOQUA).

Text Box: Waste water purification in villages in Spain

In Spain, the challenge for administrations to implement waste water purification systems in towns with less than 1 000 inhabitants stood out in the search for balance between the elimination of pollution and the economic sustainability of treatment plants. The cost of operation and maintenance of a conventional treatment plant in municipalities with more than 10,000 inhabitants could be around 10 euros per inhabitant per year, while in a town where fewer than 100 people live it would increase to 345 euros. Use of alternative technologies with lower maintenance costs, adapted to the local situation was expected to significantly reduce this economic gap. Analysis was carried out on the presence of emerging pollutants in the waters of the treatment plants of the Badajo province, such as drugs and herbicides. This highlighted analgesics as being the emerging pollutants with the highest concentration in the water entering the treatment plants, although in 90 percent of the cases, residues were eliminated during the purification process.